With the welfare of farm animals under close scrutiny in Europe, farmers there are increasingly utilising technologies and systems that balance animals’ well-being with profitability. A&G Agro recently toured a modern sow unit equipped by modern BIG DUTCHMAN technology near Vechta in Germany to witness this approach first-hand.

On a visit to a modern, trendsetting 400-sow unit near Vechta in the German state of Saxony-Anhalt, it is immediately evident that any pathogens wanting to get into this piggery will have a hard time trying. Only with prior approval are we allowed through the perimeter fence. Prior body disinfection process, decontaminated overalls and boots are mandatory to entry the farm.

Investment in the modern piggery is not cheap, but it is economically the best solution for any investor.

To achieve positive returns on the investment, it is essential to understand and utilise the housing technology to its full potential, and combine this with top pig genetics, feed, biosecurity, veterinary care and breeding management.

This results in maximum production of marketable piglets, and the greatest profitability for the sow unit, the representative explains.

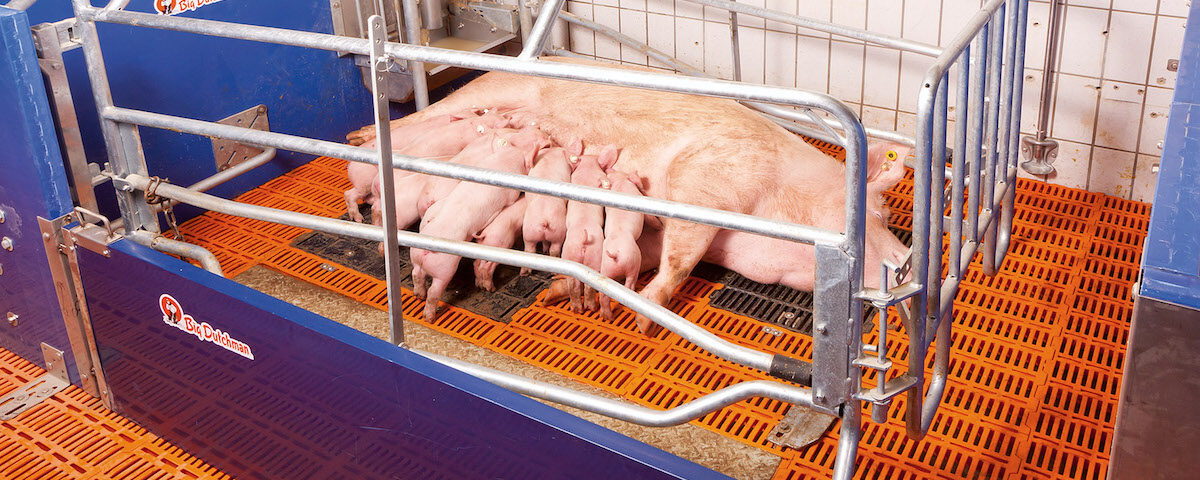

Big Dutchman International equipment is mostly used in such projects, and their specialists are always closely involved with the development and operations at the facility for achieving the balance between animal welfare and profitability,

Modern production System

An insemination door integrated into a group housing stall allows for easy handling of sows that are due for artificial insemination.

Gestating sows housed in group pens have access to multiple feeding troughs separated from each other by shoulder boards. These troughs allow all the sows to consume either liquid or dry feed at the same time without being harassed by more dominant sows.

This ensures that each gestating sow receives all the required nutrition.

The Big Dutchman electronic sow feeding (ESF) Call-Inn system has also been installed at the facility.

Every animal is identified via a unique electronic ear-tag that the automated feeding system uses to determine and supply the precise feed that a particular sow needs according to her body condition.

The pigs also enjoy playing with a system of chains attached to chew toys on one end and a swing system on the other. In addition, there is a chew stick dispenser, a sisal rope dispenser, a scratching post with playing chain, and a hay rack, all of which the pigs can safely chew on.

Balancing fresh air circulation with indoor heating, especially during Germany’s cold winters, in the closed environment is essential for optimal pig welfare.

Keeping the facility too closed-up could result in toxic ammonia levels, while excessive airflow would allow warm air to escape and risk the pigs becoming chilled.

A computerised and automated climate control system can detect any build-up of potentially dangerous gases and monitors interior temperatures. A system of motorised fresh air inlets and vents maintains air and temperature quality at levels well within European Union animal welfare parameters.

Future plans

According to the shareholders’ representative, the projected operational lifespan of the Vechta sow unit is approximately 20 years and can be modernized as needed.

We are glad to have this unique opportunity and whitnes the modern piggery production planed and executed by BIG DUTCHMAN.

We definitely will use their systems and high end technology for our upcoming projects in Africa.